Comprehensive Restoration – External & Internal Civil Works

NEW REFORMETRIX LLP™ – Civil Restoration & Advanced Construction Solutions :

We specialize in external and internal restoration works designed to enhance the life, strength, and aesthetics of buildings. Our comprehensive services include structural repairs, waterproofing, crack treatment, plastering, flooring, facade renovation, and painting solutions. Whether it involves strengthening an aging structure or upgrading a modern space, we deliver durable, visually appealing, and long-lasting restoration solutions using advanced materials such as micro concrete, polymer treatments, and protective coatings.

Our Core Civil & Restoration Services

Customer Benefits:

✔ Quality & Durability – Use of premium-grade materials and modern techniques for long-lasting structures

✔ Time-Bound Delivery – Systematic planning ensures projects are completed within committed timelines

✔ Cost-Effective Solutions – Optimized designs and efficient resource management reduce overall cost

✔ Safety & Compliance – Strict adherence to IS codes, safety norms, and government regulations

✔ Aesthetic Appeal – Blend of structural strength with modern architectural designs

✔ End-to-End Services – From foundation to finishing under one roof, reducing dependency on multiple contractors

Building Construction

We undertake all types of building construction works, delivering strong, durable, and aesthetically appealing structures tailored to client requirements. Our expertise covers residential, commercial, industrial, and institutional projects, executed with precision and compliance with modern construction standards.

Our Capabilities:

Residential Buildings – Apartments, bungalows, villas, row houses

Commercial Buildings – Offices, shops, showrooms, malls

Industrial Structures – Warehouses, sheds, factories, workshops

Institutional Buildings – Schools, hospitals, government facilities

Customized Solutions – Client-specific architectural and interior needs

Turnkey Execution – From planning and foundation to finishing and handover

Structural Works (RCC, Steel & Jacketing)

What are Structural Works?

Structural works form the backbone of any building, ensuring strength, stability, and durability. This includes RCC (Reinforced Cement Concrete) structures, steel fabrication & erection, and jacketing/retrofitting techniques for old or weak structures. Together, these systems provide safety and long-lasting performance for residential, commercial, and industrial projects.

Why Structural Works Are Important:

Safety & Stability – Protects the building against earthquakes, vibrations, loads, and weather impacts

Strengthening Old Buildings – Increases the lifespan of old or weak structures through jacketing & retrofitting

Durability – Ensures the building remains strong and damage-free for decades

Customization – Designed and executed according to residential, commercial, and industrial requirements

How We Execute Structural Works:

Design & Planning – Structural analysis and load design as per IS codes and engineering drawings

RCC Construction – Columns, beams, slabs, and footings made with high-grade concrete and steel reinforcement

Steel Structures – Industrial sheds, trusses, frames, staircases, and fabrication with on-site erection

Jacketing / Strengthening – Strengthening old or damaged columns, beams, and slabs using micro concrete, polymer mortar, or steel jacketing

Quality Testing – Cube tests, non-destructive testing (NDT), and load testing to ensure compliance and reliability

Customer Benefits:

✔ Long-Lasting Strength – High-quality RCC & steel structures provide decades of durability

✔ Safety Assurance – Earthquake-resistant and load-bearing designs reduce structural risks

✔ Cost Savings – Jacketing & retrofitting avoid costly demolition and rebuilding

✔ Time Efficiency – Modern construction methods ensure faster execution and timely handover

✔ Flexibility – Suitable for residential, commercial, and industrial projects

✔ Value Addition – A strong structure increases both property value and service life

Waterproofing & Protective Treatments

How We Execute Waterproofing & Protection:

Surface Inspection & Diagnosis – Identify leakage points, cracks, and seepage areas

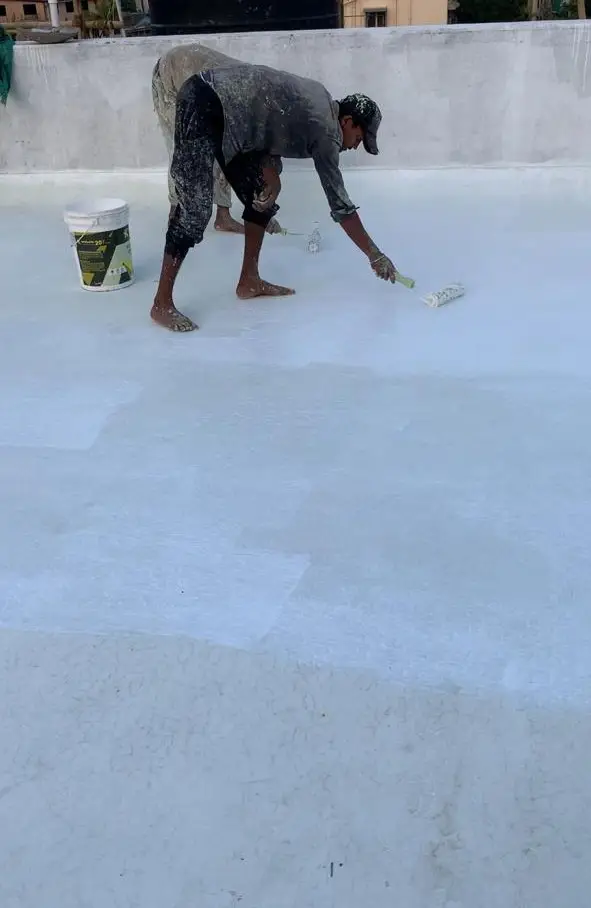

Terrace & Roof Waterproofing – Using bituminous membranes, PU coatings, or liquid-applied membranes

Basement & Tank Waterproofing – Pressure grouting, injection methods, and epoxy/polyurethane coatings

Wall & External Waterproofing – Polymer-modified coatings, crack sealing, and plaster protection

Protective Coatings – Anti-carbonation, anti-fungal, anti-corrosive, and weather-resistant finishes

Advanced Materials – Use of micro concrete, polymer treatments, and high-strength sealants for durability

Customer Benefits:

✔ Leak-Free Structures – Long-term waterproofing solutions ensure zero seepage

✔ Cost Savings – Reduces frequent repair and maintenance expenses

✔ Healthy Environment – Prevents dampness, mold, and fungus inside homes and offices

✔ Durability & Safety – Protects RCC and steel from rusting and structural weakening

✔ Value Enhancement – Maintains property aesthetics and increases resale value

✔ Advanced Technology – Use of modern polymers, coatings, and injection systems ensures lasting protection

What is Waterproofing & Protective Treatment?

Waterproofing and protective treatments are specialized processes that shield buildings from water leakage, seepage, moisture damage, and environmental deterioration. These treatments extend the life, strength, and appearance of structures by preventing corrosion, cracks, and dampness.

Why Waterproofing & Protection is Important:

Prevents Structural Damage – Stops water seepage that weakens RCC and masonry

Increases Lifespan – Protects reinforcement steel from corrosion

Improves Indoor Quality – Prevents dampness, fungus, and unhealthy living conditions

Energy Efficiency – Keeps interiors cooler and reduces maintenance costs

Aesthetic Preservation – Protects paint, plaster, and facade from weather damage

Waterproofing & Long-Term Protective Treatments

Breaking & Surface Preparation

Definition:

Breaking & surface preparation is the first and most critical step in any waterproofing or protective treatment. It involves removing old, damaged, or weak layers of concrete, plaster, or masonry, and preparing a clean, sound surface to ensure maximum bonding of subsequent waterproofing layers.

Process / How It’s Done:

Inspection & Marking

Conduct a detailed site inspection to identify cracks, damaged plaster, loose concrete, and weak areas

Mark areas requiring removal or treatment

Mechanical Breaking

Use jackhammers, chisels, and other mechanical tools to remove deteriorated concrete, plaster, or damaged tiles

Ensure careful removal to avoid damaging the underlying RCC or brick structure

Surface Cleaning

Clear all dust, debris, loose particles, and grease

Ensure the surface is free from any loose mortar, rust, fungus, or algae

Preparation of Substrate

Expose RCC reinforcement or brickwork where necessary

Make sure surface is slightly rough or porous to enhance bonding with the polymer/cement base coat

Moisture Assessment

Check for existing dampness or seepage

Dry the surface if required before applying bonding or waterproofing layers

Why This Step is Important:

Ensures proper adhesion of waterproofing and protective coatings

Removes weakened or compromised material that can cause future cracks or seepage

Provides a strong base for brick bat coba, screeding, micro-concrete, or tile finishes

Minimizes future maintenance costs by creating a durable foundation for the treatment

Customer Benefits:

✔ Leak-Free Guarantee – Proper preparation reduces chances of water ingress

✔ Durable Treatment – All subsequent layers bond perfectly, increasing lifespan

✔ Cost-Effective – Prevents future repairs and structural damage

✔ Enhanced Aesthetics – Smooth, clean base ensures high-quality finish

✔ Structural Safety – Exposes RCC/brickwork to confirm integrity before further work

Crack Treatment

How We Execute Crack Treatment:

Inspection & Assessment

Identify cracks: structural or non-structural

Measure width, depth, and cause of cracks (load, shrinkage, thermal, water seepage)

Surface Preparation

Remove loose concrete, plaster, or debris around the cracks

Clean the crack area to ensure proper bonding

Epoxy Injection for Structural Cracks

Inject high-strength epoxy resin into structural cracks

Bonds concrete back together and restores load-carrying capacity

Micro Concrete Filling for Voids & Cracks

Use micro concrete to fill voids, honeycombs, or fine cracks in slabs and beams

Ensures strengthening and seamless finish

Polymer-Based Crack Sealing

Apply polymer-modified cementitious materials for surface cracks

Provides flexibility and prevents recurring cracks

Decorative Surface Crack Repairs

For plastered or tiled walls: repair cracks without affecting aesthetics

Apply texture matching, putty, and paint for perfect finish

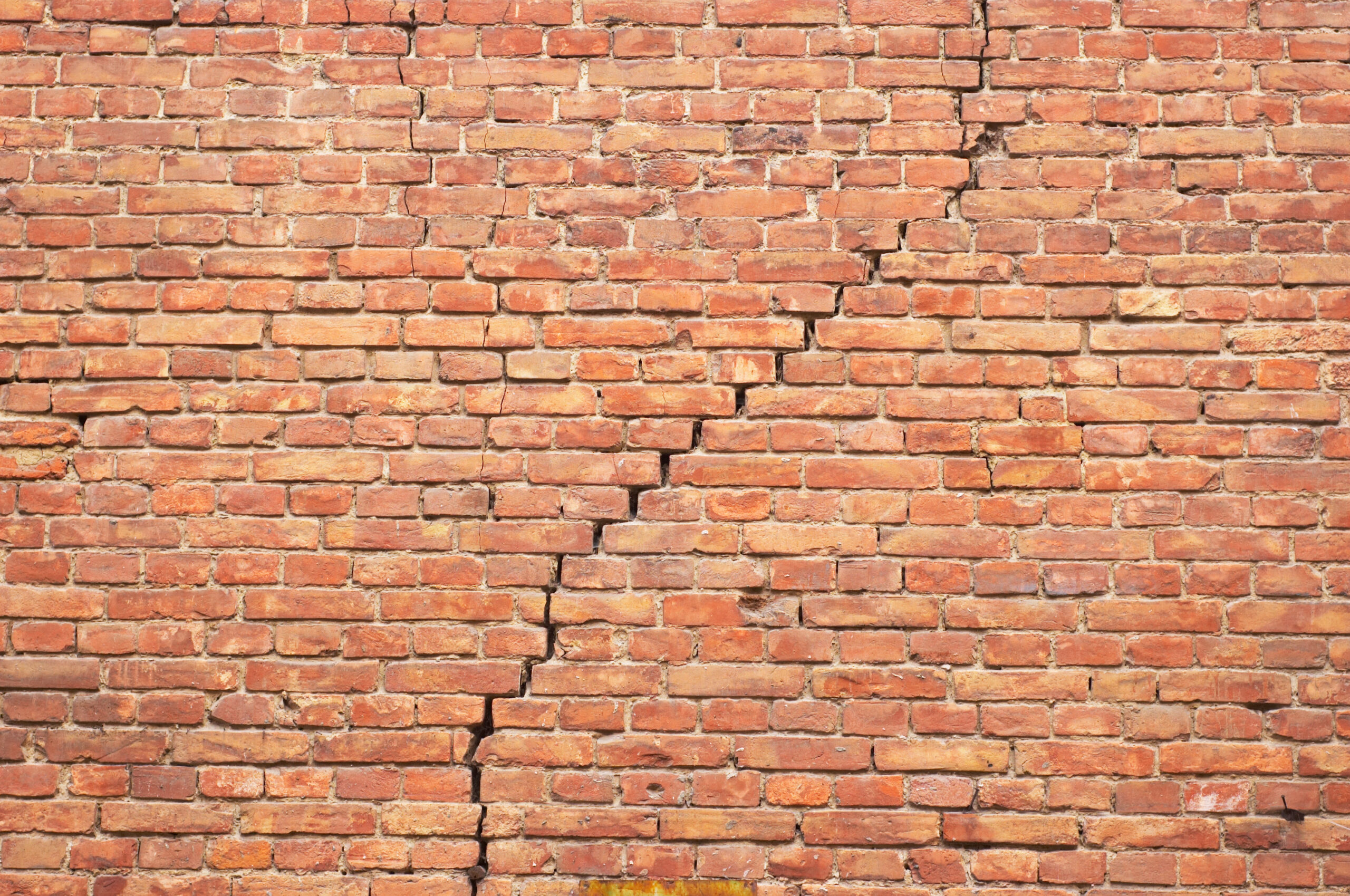

What is Crack Treatment?

Crack Treatment involves identifying, repairing, and sealing cracks in structural and non-structural elements of a building to restore strength, durability, and aesthetics. Cracks can appear in RCC slabs, beams, columns, walls, or plaster surfaces due to shrinkage, load, water seepage, or structural movements. Timely treatment prevents structural weakening, water leakage, and long-term damage.

Why Crack Treatment is Important:

Prevents Water Leakage – Seals cracks to stop seepage and dampness

Restores Structural Strength – Especially in RCC elements (slabs, beams, columns)

Prevents Corrosion – Stops reinforcement steel from exposure and rust

Improves Aesthetics – Maintains smooth, crack-free surfaces

Avoids Future Repairs – Early treatment prevents costly structural problems

Customer Benefits:

✔ Structural Safety – Ensures building stability and strength

✔ Leak & Moisture Protection – Stops dampness, seepage, and mold growth

✔ Cost Savings – Prevents major repairs or reconstruction in future

✔ Durable & Long-Lasting – High-quality epoxy, polymer, and micro concrete solutions

✔ Aesthetic Appeal – Smooth, visually appealing, and crack-free walls

✔ Customized Solutions – Suitable for residential, commercial, and industrial structures

Plastering Works

What is Plastering?

Plastering is the process of applying a layer of cement, sand, or POP (Plaster of Paris) on walls and ceilings to achieve a smooth, even, and durable surface. It serves both structural and aesthetic purposes, providing protection to walls from moisture, cracks, and environmental damage while preparing surfaces for painting or finishing.

Why Plastering is Important:e

Protects Walls – Prevents moisture penetration, cracks, and structural damage

Improves Durability – Extends the life of masonry and structural surfaces

Smooth Finish for Decoration – Essential base for painting, wall tiles, or cladding

Environmental Protection – Guards against rain, sunlight, and temperature changes

How We Execute Plastering Works:re

Surface Preparation

Clean walls and ceilings, removing dust, debris, or loose particles

Apply a primer or bonding coat to enhance adhesion of the plaster

Internal Wall Plastering

Cement-sand or POP plaster for interiors

Smooth leveling and finishing

Crack-free surfaces with polymer-enhanced plaster

External Wall Plastering / Rendering

Cement-sand plaster or weatherproof rendering for external walls

Protective coatings applied for resistance against water, weather, and UV

Finishing

Smooth trowel finish for plain walls

Textured or decorative finishes as per client requirement

Ready for painting, wall cladding, or tiling

Customer Benefits:

✔ Durable & Strong Walls – High-quality plaster enhances structural integrity

✔ Aesthetic Appeal – Smooth, even, and crack-free surfaces ready for painting

✔ Low Maintenance – Polymer-enhanced plaster reduces risk of cracks and repairs

✔ Customizable Finishes – Interior or exterior textures, plain or decorative finishes

✔ Water & Weather Resistance – Keeps walls safe from moisture, dampness, and environmental wear

✔ Value Addition – Well-plastered walls improve building appearance and market value

Flooring Works

How We Execute Flooring Works:

- Surface Preparation

Leveling and cleaning of the base surface

Removal of old flooring or debris

Ensuring proper slope and alignment for drainage where needed

Material Selection

Tiles: vitrified, ceramic, or porcelain

Natural stones: marble, granite, sandstone

Polymer-modified concrete for industrial or heavy-traffic areas

Installation Process

Laying tiles/stones with high-quality adhesives

Polymer-modified concrete applied where heavy load-bearing is required

Joint filling and surface leveling for a smooth, even finish

Finishing

Polishing marble/granite surfaces

Anti-skid finishes for safety

Ensuring alignment, color uniformity, and smooth edges

Customer Benefits:

✔ Durability & Strength – Long-lasting flooring for residential, commercial, and industrial spaces

✔ Aesthetic Enhancement – Beautiful, polished, and uniform surfaces

✔ Low Maintenance – High-quality materials reduce wear and tear

✔ Safety & Comfort – Anti-skid finishes for wet areas, proper leveling for safe walking

✔ Customizable Options – Tiles, marble, granite, or polymer concrete depending on client needs

✔ Value Addition – Upgrades property appearance and market value

What is Flooring?

Flooring involves the installation or repair of surface layers on floors using materials such as tiles, marble, granite, stone, or polymer-modified concrete. Flooring not only enhances the aesthetic appeal of a space but also ensures durability, safety, and ease of maintenance for residential, commercial, and industrial areas.

Why Flooring is Important:

- Provides durable, stable, and safe surfaces for movement

Enhances aesthetic appeal of interiors and exteriors

Reduces maintenance costs due to long-lasting materials

Ensures resistant surfaces for high traffic, industrial, or wet areas

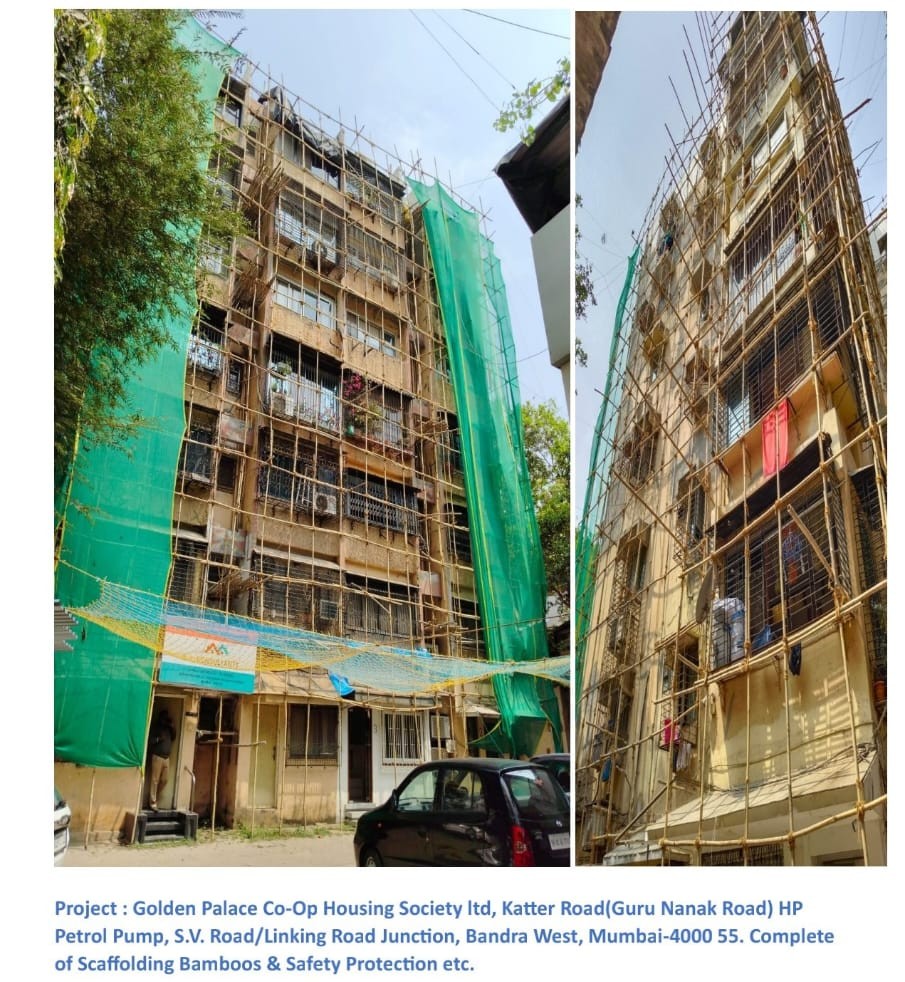

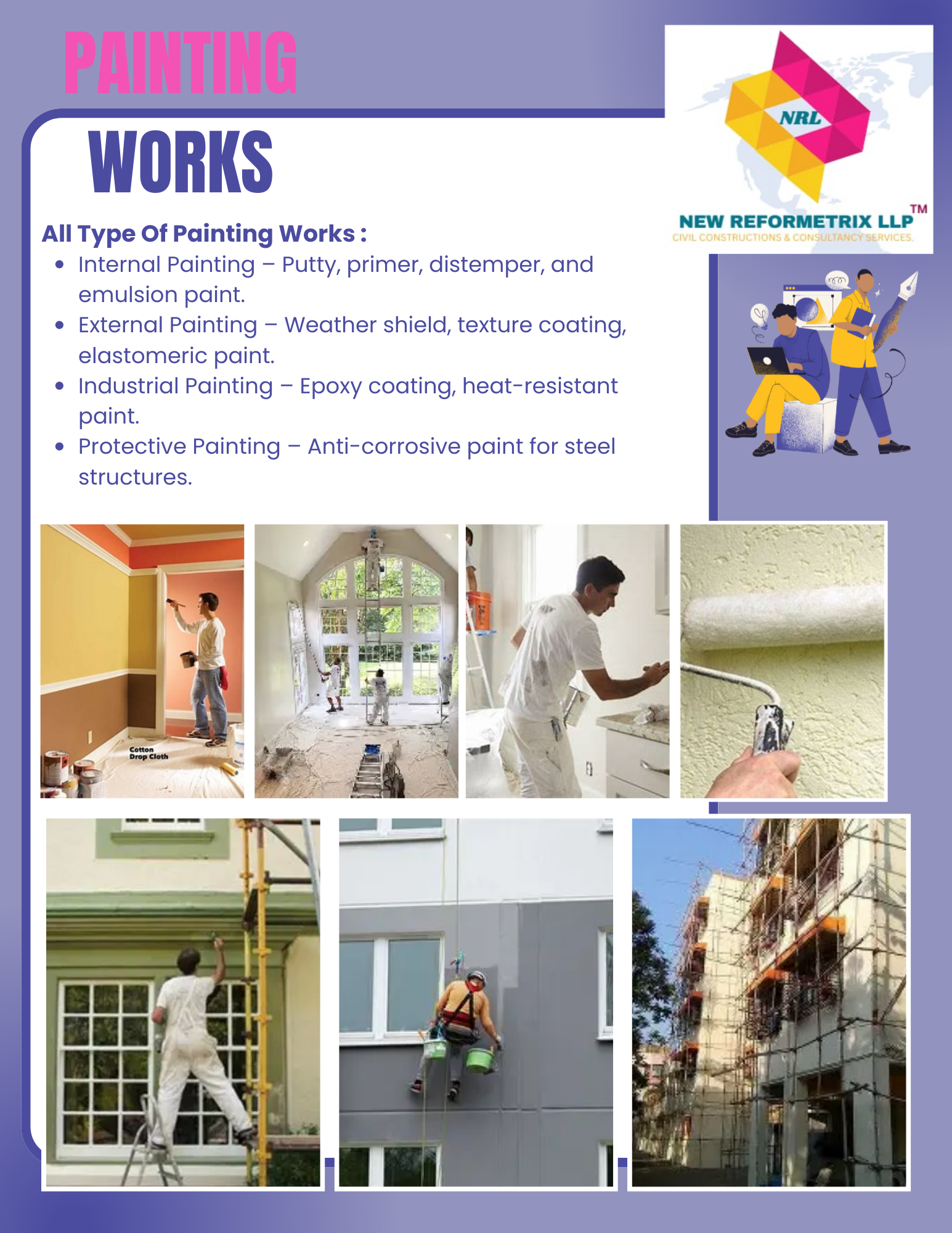

EXTERNAL & INTERNAL PAINTING WORK

Introduction

At NEW REFORMETRIX LLP : External Painting Work plays a vital role in protecting and beautifying the exterior surface of a building.

Constant exposure to sunlight, rain, dust, and pollution causes the external walls to fade, peel, and develop cracks or dampness.

Through external painting, the building regains its fresh appearance, weather resistance, and long-lasting durability.

At NEW REFORMETRIX LLP

Scope of Work

Surface Preparation

Removing old paint, dirt, algae, and loose plaster.

Cleaning the surface using wire brushing or pressure washing.

Filling all surface cracks and holes with suitable crack filler or putty.

Leveling and smoothing the surface for uniform finishing.

Priming

Applying a high-quality exterior acrylic primer for better paint adhesion.

Primer acts as a protective base, preventing moisture and alkalinity damage.

Painting Application

Using premium-grade weatherproof paints (Asian Paints Apex Ultima, Nerolac Excel, Berger Weathercoat, etc.).

Applying two or more coats for an even and durable finish.

Using brush, roller, or spray techniques as per site conditions.

Texture & Decorative Finishes (if required)

Application of designer textures such as sand finish, rustic, or roller texture.

Dual-tone or patterned finishes for enhanced visual appeal.

Safety & Scaffolding

Erection of safe double bamboo or MS pipe scaffolding for exterior work.

Workers equipped with proper safety gear (helmets, belts, gloves, shoes).

Site cleaning and proper handover after completion.

Materials Used

Exterior-grade acrylic primer

Crack filler and wall putty

Weatherproof or elastomeric paints

Anti-fungal and anti-algae coatings

Texture materials (as per design)

Advantages

Provides strong protection against weather, sunlight, and moisture.

Prevents cracks, peeling, and dampness.

Enhances the aesthetic appeal and gives the building a fresh new look.

Increases property value and extends the life of the structure.

Ensures easy maintenance for several years.

Quality Assurance

At Meena Civil Construction & Developers, we ensure:

Use of branded, ISI-certified paints and materials.

Strict adherence to manufacturer’s specifications and proper application methods.

Skilled painters and on-site supervision for quality control.

Adequate drying and curing time for long-lasting results.

Result

A durable, elegant, and weather-resistant exterior finish that enhances both the appearance and protection of the building for years to come.

Introduction

At NEW REFORMETRIX LLP : Internal Painting Work enhances the aesthetic appeal, cleanliness, and comfort of the building interiors.

Over time, internal walls are affected by stains, cracks, moisture, and discoloration due to routine wear and tear.

A well-executed internal painting job not only provides a fresh and elegant look but also protects surfaces from damage and improves the overall ambience of the premises.

Scope of Work

Surface Preparation

Removing old paint, dust, and loose particles from the surface.

Scraping and cleaning walls with sandpaper for a smooth base.

Filling cracks, holes, and undulations with wall putty or POP.

Ensuring complete surface leveling before applying paint.

Priming

Applying one coat of interior-grade primer to ensure better paint adhesion and coverage.

Primer helps in sealing the surface and improving the final finish.

Putty & Finishing

Two coats of acrylic wall putty for a uniform, smooth, and durable surface.

Proper sanding after each coat to achieve perfect finish quality.

Painting Application

Applying high-quality interior emulsion paints such as Asian Paints Royale, Nerolac Beauty Gold, or Berger Silk.

Two or more coats applied evenly with brush or roller.

Ensuring smooth, stain-free, and washable surface finish.

Special Finishes (If Required)

Designer finishes like texture, stencil art, metallic or velvet touch.

Ceiling painting with distemper or emulsion.

Door, window, and grill painting with enamel or PU coatings.

Safety & Cleanliness

Proper masking of electrical fittings, furniture, and flooring.

Maintaining site cleanliness throughout the painting process.

Final cleanup and polishing after completion.

Materials Used

Interior-grade primer

Acrylic wall putty / POP

Premium emulsion paints (washable and low-VOC)

Enamel paint for wood and metal

Masking tape, sandpaper, rollers, and brushes

Advantages

Enhances the look and feel of interiors with elegant finishing.

Provides smooth, washable, and long-lasting walls.

Improves light reflection and brightness of rooms.

Prevents surface deterioration and ensures easy maintenance.

Adds value and comfort to the living or working environment.

Quality Assurance

At Meena Civil Construction & Developers, we ensure:

Use of branded and eco-friendly paints.

Skilled workforce and professional supervision.

Proper surface preparation and curing time for best results.

Neat, clean, and dust-free execution from start to finish.

Result

A vibrant, clean, and premium-quality interior finish that transforms your building interiors into a modern, fresh, and pleasant environment.

ADVANCED MATERIAL TREATMENT & JACKETING MICRO-CONCRETE WORK

At NEW REFORMETRIX LLP Scope of Work

Structural Inspection & Assessment

Detailed examination of all RCC members to identify damages, cracks, honeycombing, and corrosion.

Marking and quantifying areas that require repair or jacketing.

Preparing a detailed repair methodology and sequence of execution.

Surface Preparation

Breaking and removing all loose and damaged concrete.

Exposing corroded reinforcement steel carefully without damaging the structure.

Cleaning the reinforcement with wire brush or sandblasting to remove rust and scaling.

Advanced Material Treatment

Applying Rust Remover to clean reinforcement.

Coating reinforcement with Anti-Corrosive Protection to prevent further rusting.

Applying Bonding Agent (SBR / Acrylic Polymer) on old concrete surface for excellent adhesion with new material.

Jacketing / Micro-Concrete Application

Fixing additional steel reinforcement (if required) for strengthening.

Installing shuttering or formwork with proper alignment and sealing.

Pouring Micro-Concrete (ready-mix, non-shrink, flowable grade) into the formwork.

Ensuring proper curing for achieving designed strength and smooth finish.

Finishing & Protection

Removing shuttering after setting period.

Applying polymer-modified mortar or waterproof coating on treated areas.

Surface finishing for uniform texture and alignment with existing structure.

Introduction

At NEW REFORMETRIX LLP With time, many buildings experience structural deterioration due to corrosion of reinforcement, cracking, and environmental exposure.

To restore the strength, stability, and durability of such structures, Advanced Material Treatment and Jacketing Work using Micro-Concrete is one of the most effective rehabilitation techniques.

This process ensures long-term protection of RCC members like columns, beams, slabs, and chajjas, and helps in restoring the original load-bearing capacity of the structure.

At NEW REFORMETRIX LLP Materials Used

Rust remover and anti-corrosive coating

SBR / Acrylic bonding agent

Non-shrink Micro-Concrete (Ready-mix or site-mix)

High-strength cementitious grout

Polymer-modified repair mortar

Curing compound / waterproof coating

Advantages

Restores original strength of damaged structural members.

Provides excellent bonding between old and new concrete.

Prevents further corrosion of reinforcement.

Increases load-bearing capacity and durability of the structure.

Ensures non-shrink, dense, and crack-free repairs.

Minimizes downtime and ensures long-term structural stability.

Quality & Execution

At Meena Civil Construction & Developers, we ensure:

Execution under experienced structural engineers and site supervisors.

Use of tested and certified repair materials.

Proper curing, alignment, and formwork sealing to avoid leakage.

Complete adherence to IS 15988:2013 (Repair and Rehabilitation Code of Practice).

Detailed documentation and photographic record of every stage.

Result

A strong, durable, and corrosion-resistant structure, restored with advanced materials and modern techniques, ensuring extended service life and structural safety.

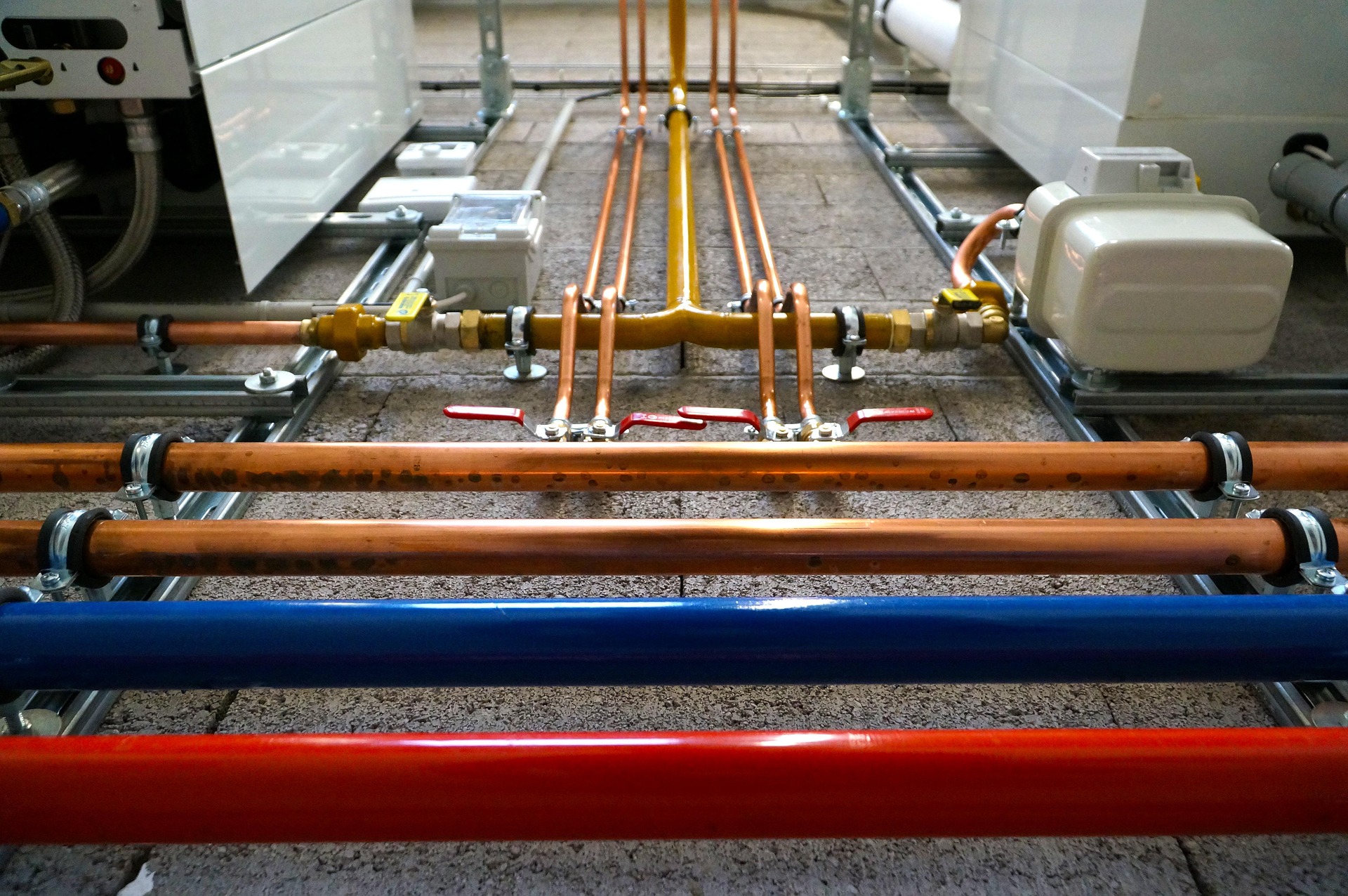

EXTERNAL PLUMBING COMPLETE WORKS

Introduction

The External Plumbing System of a building plays a vital role in ensuring smooth water distribution and efficient drainage.

Over time, external pipelines and fittings are affected by corrosion, leakages, blockages, and weathering, which can lead to water wastage and structural damage.

At NEW REFORMETRIX LLP, we provide complete external plumbing solutions — from installation to replacement and maintenance — using advanced materials and professional techniques to ensure long-lasting and leak-proof systems.

Advantages

Ensures leak-proof and efficient water flow system.

Reduces maintenance cost and water loss.

Uses durable and weather-resistant materials.

Enhances building hygiene and water management.

Increases system longevity and reliability.

Quality Assurance

At NEW REFORMETRIX LLP, we ensure:

Use of standard-approved materials and branded fittings.

Work executed by qualified plumbers under skilled supervision.

Compliance with plumbing codes and IS standards.

Thorough testing and verification before handover.

Timely completion with neat and professional workmanship.

Result

A robust, leak-proof, and maintenance-free external plumbing system — ensuring smooth water supply, efficient drainage, and long-term durability of the building.

Scope of Work

Inspection & Planning

Detailed survey of the existing external plumbing layout.

Identifying damaged, leaking, or corroded pipelines and fittings.

Planning new pipeline routes, water supply lines, and drainage systems as per design.

Dismantling & Replacement

Careful removal of old, rusted, or damaged GI / PVC / CPVC / HDPE pipelines.

Cleaning of joints and wall surfaces before new installation.

Safe disposal of dismantled material and debris.

New Plumbing Installation

Supply and installation of CPVC / UPVC / HDPE / GI pipes of approved make and class.

Proper fitting with brass / UPVC / SS fittings, tees, elbows, unions, and valves.

Use of solvent cement, thread seal tape, and leak-proof joints for durability.

Installation of air vents, drainage lines, and overflow systems where necessary.

Support & Clamping

Fixing of pipes with MS clamps and supports at required intervals.

Use of anti-corrosive coated clamps for long life.

Maintaining uniform alignment and slope for proper flow.

Testing & Commissioning

Hydraulic pressure testing for water supply lines.

Checking for leakage, pressure, and flow efficiency.

Final inspection and approval before plastering or concealment.

Finishing & Protection

Concealment of pipes in wall chases (if required) with proper covering.

Application of weatherproof and UV-resistant paint on exposed lines.

Ensuring all joints are accessible for maintenance.

Materials Used

Pipes: CPVC / UPVC / HDPE / GI (as per design)

Fittings: Brass, SS, or UPVC of ISI-approved brands

Valves & Accessories: Ball valves, NRVs, air vents, drain traps, elbows, tees

Sealants: Solvent cement, thread seal tape, rubber washers

Support Materials: MS clamps, hangers, anchors, anti-corrosive coatings

INTERNAL PLUMBING COMPLETE WORKS

Scope of Work

Inspection & Planning

Detailed survey of existing internal plumbing system.

Identifying leaking, corroded, or blocked pipelines and faulty fixtures.

Designing a comprehensive plumbing layout for supply and drainage.

Dismantling & Replacement

Removal of old or damaged CPVC, UPVC, or GI pipes and fittings.

Cleaning walls and pipe routes for new installation.

Safe disposal of dismantled pipes and debris.

Pipe & Fixture Installation

Supply and installation of CPVC / UPVC / GI pipes of approved make.

Fitting of brass, SS, or UPVC valves, elbows, tees, unions, and couplings.

Installation of sinks, taps, water closets, shower units, and drainage connections.

Use of thread seal tape, solvent cement, and rubber gaskets for leak-proof joints.

Support & Alignment

Proper fixing of pipes with MS clamps, hangers, and supports at recommended intervals.

Ensuring proper slope for drainage lines and uniform alignment for water supply lines.

Application of anti-corrosive coating on exposed supports.

Testing & Commissioning

Hydrostatic pressure testing of water supply lines.

Leak detection, flow testing, and verification of drainage efficiency.

Final inspection and handover after ensuring complete functionality.

Finishing & Protection

Concealment of pipelines in wall chases or false ceilings (if required).

Painting or coating exposed pipes for protection and aesthetics.

Ensuring all access points are functional for maintenance.

Introduction

Internal Plumbing is a critical component of any building, ensuring smooth water supply, proper drainage, and hygiene within residential, commercial, or industrial structures.

Over time, internal pipelines, fixtures, and joints may suffer from leakages, corrosion, blockages, and wear.

At NEW REFORMETRIX LLP, we provide complete internal plumbing solutions, from installation to maintenance, using high-quality materials and professional techniques for long-lasting, efficient, and leak-proof systems.

Materials Used

Pipes: CPVC, UPVC, or GI (ISI-approved brands)

Fittings: Brass, Stainless Steel, or UPVC

Valves & Accessories: Ball valves, Non-Return Valves (NRV), waste pipes, traps

Sealants: Thread seal tape, Solvent cement, Rubber washers

Supports: MS clamps, hangers, anchors with anti-corrosive coating

Advantages

Provides efficient and leak-free internal water supply and drainage.

Reduces maintenance costs and water wastage.

Uses durable, corrosion-resistant, and high-quality materials.

Ensures hygiene, safety, and smooth functionality.

Enhances building reliability and long-term performance.

Quality Assurance

At NEW REFORMETRIX LLP, we ensure:

Use of ISI-certified pipes, fittings, and valves.

Installation by experienced and skilled plumbers.

Strict adherence to plumbing codes and IS standards.

Thorough testing and commissioning before handover.

Timely completion with neat, professional, and safe execution.

Result

A durable, leak-proof, and fully functional internal plumbing system, providing efficient water supply, effective drainage, and enhanced building hygiene for years to come.

DRAINAGE WORKS

Introduction

Efficient drainage systems are crucial for the health, hygiene, and safety of any building or society.

Drainage works ensure smooth disposal of wastewater, rainwater, and sewage, preventing waterlogging, seepage, and structural damage.

At NEW REFORMETRIX LLP, we provide complete drainage solutions, from installation to maintenance, using high-quality materials and modern techniques to ensure long-lasting, clog-free, and hygienic systems.

Scope of Work

Survey & Planning

Detailed inspection of existing drainage system.

Identifying damaged pipes, choked drains, or leakage points.

Designing new drainage layouts with proper slope and capacity.

Dismantling & Cleaning

Removal of old, damaged, or corroded pipes and manholes.

Cleaning existing drainage channels and underground pipes.

Safe disposal of debris and waste material.

Drainage Pipe Installation

Laying of HDPE / RCC / UPVC / GI pipes as per design.

Installation of manholes, inspection chambers, gullies, and traps.

Proper alignment, slope, and bedding to ensure efficient flow.

Quality Assurance

At NEW REFORMETRIX LLP, we ensure:

Use of ISI-certified materials and durable components.

Skilled workforce and experienced supervision for precise execution.

Proper alignment, slope, and jointing for leak-proof performance.

Compliance with all local plumbing and drainage codes.

Timely completion with clean, safe, and professional execution.

4 Joints & Connections

Leak-proof connections using rubber gaskets, solvent cement, or jointing compounds.

Integration of external and internal drainage lines.

Connections to municipal sewer or treatment systems.

5 Manhole & Catch Basin Construction

Construction of reinforced concrete manholes with covers.

Installation of catch basins for stormwater collection.

Ensuring accessibility for maintenance and cleaning.

6 Testing & Commissioning

Hydraulic and flow testing for leaks and blockages.

Ensuring free flow and proper gradient of pipelines.

Final inspection and handover after verification.

Materials Used

Pipes: HDPE, UPVC, GI, or RCC (as per project requirements)

Manholes & Covers: RCC or cast iron

Fittings: Tees, elbows, couplings, traps, and bends

Sealants & Jointing Compounds: Solvent cement, rubber gaskets

Bedding & Backfill: Sand, gravel, and approved soil mix

Advantages

Ensures efficient wastewater and stormwater disposal.

Prevents waterlogging, dampness, and seepage.

Enhances hygiene and sanitation of the building or society.

Reduces maintenance frequency and repair costs.

Provides durable and long-lasting drainage infrastructure.

Result

A robust, efficient, and fully functional drainage system that ensures hygienic, leak-proof, and maintenance-friendly wastewater management for the building or society.

PAVER BLOCK WORKS

Scope of Work

Site Preparation

Clearing of site area from debris, vegetation, and unwanted materials.

Excavation to required depth based on load-bearing requirements.

Leveling and compaction of subgrade with proper slope for drainage.

Base Layer Construction

Laying sub-base layer using well-graded granular material or crushed stone.

Compaction of sub-base with mechanical rollers or vibratory compactors.

Installation of bedding layer of coarse sand (usually 30–40 mm thick) for leveling.

Paver Block Laying

Supply and laying of ISI-standard concrete paver blocks in approved patterns (herringbone, basketweave, or running bond).

Ensuring uniform gaps (2–5 mm) between blocks for interlocking.

Cutting blocks at edges for proper alignment and finishing.

Joint Filling & Compaction

Filling joints with fine sand to lock paver blocks.

Vibratory compaction to level surface and ensure strong interlocking.

Re-filling of sand in joints after initial settlement.

Edging & Finishing

Installation of concrete / stone curbs or kerbs to prevent lateral movement.

Final leveling, cleaning, and removal of excess sand.

Ensuring proper slope for stormwater drainage.

Quality Testing

Checking level, slope, and alignment across the paved area.

Verification of block strength and compaction.

Ensuring no loose or uneven blocks for long-term durability.

Materials Used

Paver Blocks: Precast concrete blocks, 60–80 mm thick (as per traffic load)

Base Material: Crushed stone / gravel for sub-base layer

Bedding Layer: Coarse sand (30–40 mm)

Joint Filling: Fine sand

Edge Restraints: Concrete or stone curbs

Optional: Interlocking polymeric sand for heavy traffic areas

Introduction

Paver blocks are precast concrete units used for constructing durable, aesthetic, and load-bearing surfaces such as roads, walkways, parking areas, and plazas.

Paver Block Works involve proper design, leveling, laying, jointing, and finishing to ensure long-lasting, stable, and visually appealing surfaces.

At Meena Civil Construction & Developers, we specialize in high-quality paver block installation, using premium materials and modern construction techniques.

Advantages

Durable and long-lasting compared to conventional asphalt or concrete surfaces.

Easy maintenance and replacement — damaged blocks can be replaced individually.

Aesthetic appeal — available in different colors, patterns, and textures.

Load-bearing capability — suitable for pedestrian and vehicular traffic.

Eco-friendly — allows water infiltration, reducing surface runoff.

Prevents cracks and uneven surfaces due to interlocking nature.

Quality Assurance

At Meena Civil Construction & Developers, we ensure:

Use of ISI-certified, high-strength paver blocks.

Proper compaction, leveling, and joint filling.

Skilled supervision during laying and finishing.

Compliance with traffic load, drainage, and quality standards.

Long-lasting, safe, and visually pleasing paved surfaces.

Result

A strong, durable, and aesthetically appealing paved surface that provides smooth traffic movement, excellent load distribution, and minimal maintenance, suitable for residential, commercial, or industrial areas.

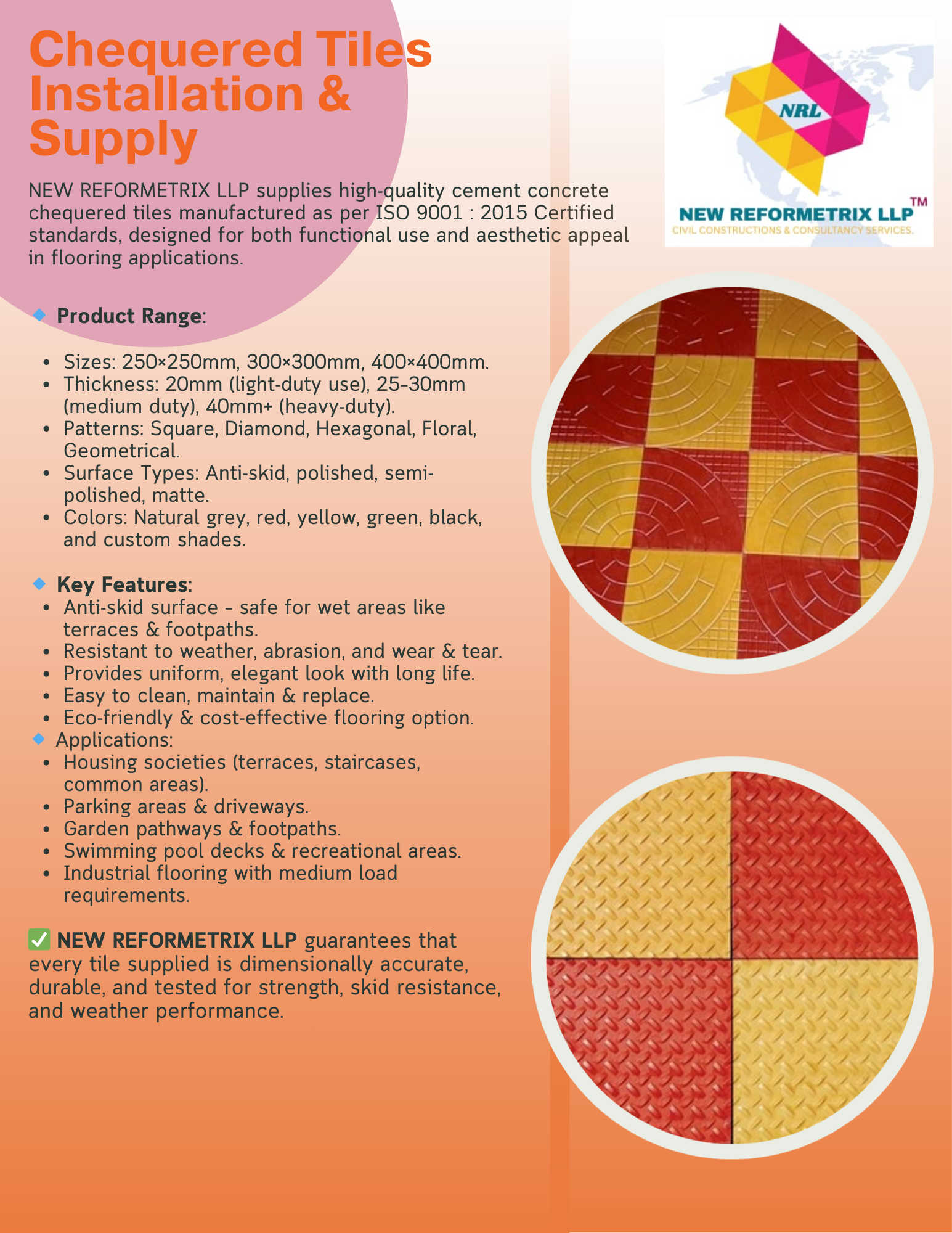

Expert Consultancy & Civil Construction Services

NEW REFORMETRIX LLP is a leading Consultancy and Civil Construction Service Company based in Titwala, Kalyan, Thane. We specialize in providing comprehensive civil engineering solutions, including structural audits, restoration works, waterproofing, civil repairs, and specialized flooring services like chequered tile works. Our team of experienced engineers and certified professionals ensures that every project is executed with precision, using high-quality materials and industry-standard techniques. From detailed documentation and compliance reports to flawless execution, NEW REFORMETRIX LLP delivers durable, safe, and aesthetically superior construction solutions, tailored to meet the needs of residential, commercial, and industrial clients.

1. Materials Used

Chequered Tiles:

Material: Precast Cement Concrete (PCC)

Size: 300×300 mm, 250×250 mm, or as specified

Thickness: 20–30 mm

Grade: M-20 or M-25 as per IS Certified

Finish: Non-slip / Anti-skid pattern (Diamond, Square, I-shape, etc.)

Colour: Red, Grey, Yellow, or Custom shades as approved

Base Mortar:

Ratio: 1:4 (Cement : Coarse sand)

Thickness: 20–25 mm average

Cement conforming to IS 269 or IS 12269

Joint Filling:

Neat cement slurry (1.75 kg/sq.m.) for bonding

White or coloured cement slurry for joints

Curing Material:

Clean water, 7 days minimum curing period

3. Surface Preparation

The base surface is cleaned, levelled, and made free from dust, oil, and loose materials.

Proper slope (1:100) is maintained for easy drainage of rainwater.

Necessary markings and edge alignments are made before laying tiles.

A compacted sub-base of PCC (M-10 or M-15) may be provided where required.

4. Laying Procedure

Setting Out: Mark the area and define tile pattern layout.

Mortar Bed: Spread cement mortar (1:4) evenly to required thickness.

Laying Tiles: Place the chequered tiles gently over the mortar bed with cement slurry applied to the bottom face for better adhesion.

Tapping & Levelling: Tap each tile lightly with a wooden mallet to ensure uniform level and contact.

Joint Filling: Fill all joints with neat cement or coloured slurry.

Cleaning: Wipe excess cement slurry from the surface using a wet sponge.

Curing: Keep the surface moist for at least 7 days to achieve proper bonding and strength.

5. Quality Control

Ensure uniform thickness, proper slope, and tight joints (≤3 mm gap).

Check tiles for cracks, uneven colour, or surface damage before fixing.

Verify line, level, and pattern as per approved drawing.

Use of straight edge, level, and plumb bob during laying.

Non-skid test and water absorption test as per IS Mark Quality.

6. Mode of Measurement

Measurement taken in square meters (m²) for the finished tile surface area.

Deductions are made for openings above 0.1 m².

7. Advantages

✅ Durable and long-lasting surface

✅ Anti-skid and safe for walking

✅ Visually appealing with colour variety

✅ Easy maintenance and water drainage

✅ Economical compared to natural stone flooring

8. Typical Application Areas

Building terraces

Parking areas

Society compounds

Pathways and footpaths

Balconies and podiums

Garden pavements and driveways

9. Finishing & Cleaning

After curing, the entire surface is cleaned using mild detergent and water to remove cement stains. Proper sealant or coating may be applied for enhanced shine and water resistance, if specified by the client.

10. Safety & Precautions

Use safety gloves and boots while handling cement tiles.

Avoid laying tiles under direct sunlight to prevent premature setting.

Maintain slope for drainage to avoid water stagnation.

Ensure edge cutting with tile cutter for neat border finishing.